Overview

STEM careers

Time

Materials

Per Team of 3-4 Students, Phase 1:

|

Per Class, Phase 2:

|

Instructions

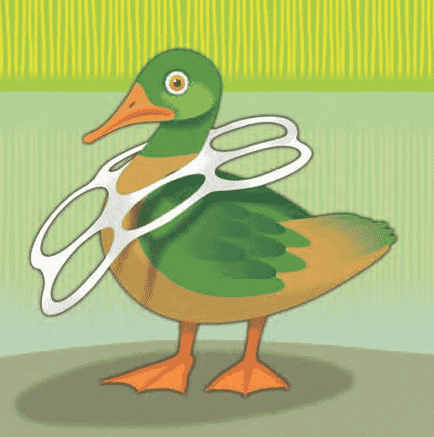

Students experience product and process design as they create a beverage can holder that won’t harm wildlife or pollute but that is sturdy and easy to carry. Caution: Let students know that opening and/or drinking the beverages is not a part of this activity!

-

After students learn their challenge, demonstrate the problem with plastic rings by asking students to put a rubber band around their right wrist and then get it off, using only their right hand and nothing else.

After students learn their challenge, demonstrate the problem with plastic rings by asking students to put a rubber band around their right wrist and then get it off, using only their right hand and nothing else. - Discuss the criteria for their new design. It has to:

- Hold 6 cans

- Be sturdy

- Be easy to carry

- Be harmless to wildlife

- Have low or no environmental impact

- Be made out of the available materials

- Divide the students into teams of 3–4 and instruct them to:

- Brainstorm possible solutions.

- Choose the one that best meets the criteria and constraints.

- Make a prototype out of the materials. Consider different kinds of handles, ways to arrange the cans, how to remove the cans, and impact on animals.

- Test and evaluate the prototype. If the holder bends and twists, teams will need to reinforce their design.

- If it fails in some way, redesign and retest.

- Choose the design that best meets the criteria and constraints. Explain that the class will now use this design to manufacture beverage holders.

- Organize the class into one or two assembly lines, with the students as the operators of the line. Test make a holder or two to get the line running smoothly.

- Divide the class into 2 teams. The first team manufactures holders in the assembly line. In the second team, each student manufactures holders individually. Announce that you are the Senior Quality Control Officer who will check on the quality of the manufactured holders.

- Set a timer for 10–15 minutes. See how many holders students can make and whether they vary in quality.

Guiding questions

- If an animal ate your holder, what would happen?

- If you could use different materials, what would you pick and why?

- If you could make a holder for a different number of cans, how would it affect your design?

Engineering & science connections

- Engineers look for ways to improve packaging systems to reduce litter and the need for raw materials, eliminate dangers to animals and the environment, and keep the production process cost-effective. To make these improvements, engineers develop prototypes and test them to discover an idea’s strengths and weaknesses. They usually go back to the design phase many times before coming up with a really great idea.

- One of the biggest problems with the traditional plastic can holder is that it is dangerous to wildlife. In the ocean, there are gyres produced due to the currents of the ocean. These gyres collect garbage and especially plastic into one location. Wildlife feed in these locations making it very dangerous for them.

- Although six-pack rings are now made from photodegradable plastic, which allows them to degrade when exposed to light, it can take up to 90 days, and still much of the plastic never fully breaks down. These smaller pieces are toxic to the marine animals that mistake them for food. Engineers are working to create alternative can holders and have already designed 100 percent biodegradable and even edible (made from barley, corn, etc.) packaging!

Activity adapted from Design Squad Nation. Design Squad Nation is produced by WGBH Boston. Major funding is provided by the National Science Foundation. Project funding is provided by Northrop Grumman Foundation and S.D. Bechtel, Jr. Foundation. Additional funding is provided by United Engineering Foundation (ASCE, ASME, AIChE, IEEE, AIME). This DESIGN SQUAD NATION material is based upon work supported by the National Science Foundation under Grant No. EEC-1129342. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.TM/© 2011 WGBH Educational Foundation.

This is a great idea to teach both concepts!